Internet Explorer, Chrome Browser, Firefox Browser, Safari Browser

Siemens at the SPS 2019

Nuremberg, 26 November to 28 November 2019

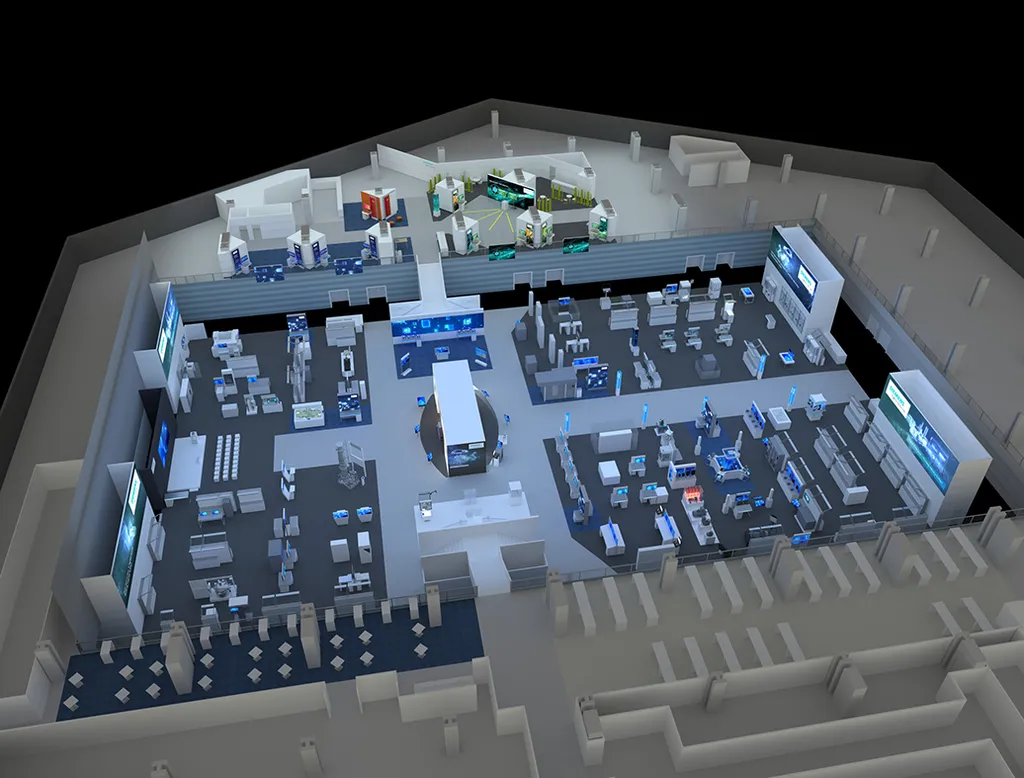

Save the date2019-11-26T00:00:002019-11-28T00:00:00Europe/Parisuse-titleSiemens at the SPS 2019At "SPS – Smart Production Solutions" 2019, Siemens will present sector-specific applications and future technologies for the digital transformation of the discrete and process industries. At the heart of the 4000 square meter booth will be new products, solutions and services from the Digital Enterprise portfolio, which can be used to merge the real and virtual world.

Nuremberg

On November 26, the first day of SPS, Klaus Helmrich spoke at the Siemens press conference, which took place in the trade show Convention Center. Mr Helmrich discussed the latest trends in digitalization and the next stage of digital transformation in the discrete and process industries.

At "SPS – Smart Production Solutions" 2019, Siemens will present sector-specific applications and future technologies for the digital transformation of the discrete and process industries. At the heart of the 4000 square meter booth will be new products, solutions and services from the Digital Enterprise portfolio, which can be used to merge the real and virtual world.

Save the date2019-11-26T00:00:002019-11-28T00:00:00Europe/Parisuse-titleSiemens at the SPS 2019At "SPS – Smart Production Solutions" 2019, Siemens will present sector-specific applications and future technologies for the digital transformation of the discrete and process industries. At the heart of the 4000 square meter booth will be new products, solutions and services from the Digital Enterprise portfolio, which can be used to merge the real and virtual world.

Nuremberg

On November 26, the first day of SPS, Klaus Helmrich spoke at the Siemens press conference, which took place in the trade show Convention Center. Mr Helmrich discussed the latest trends in digitalization and the next stage of digital transformation in the discrete and process industries.

Press Release26 November 2019

Siemens integrates cutting-edge technologies for more environmentally efficient and flexible production

- Digital Enterprise portfolio aimed at meeting increasing requirements for greater productivity and flexibility as well as environmental efficiency...

Press Release02 October 2019

Siemens presents extended Digital Enterprise portfolio for more effective use of digital data

- This year’s trade fair slogan: "Digital Enterprise – Thinking industry further!"...

International Siemens Press Conference at Smart Production Solutions (SPS) 2019

Tuesday, November 26,

2019, 1:00 PM

NCC Ost, Level 2, at the Nuremberg Convention Center

Room St. Petersburg

NCC Ost, Level 2, at the Nuremberg Convention Center

Room St. Petersburg

In the Press

Conference, Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO

Digital Industries, explained how Siemens is using its Digital Enterprise

portfolio to help companies in the manufacturing and process industry to reach

the next level of digital transformation: with solutions, which are tailored to

the specific requirements of individual sectors. The advantages and new

potential opportunities offered by future technologies such as Cloud and Edge

Computing, Artificial Intelligence or Industrial 5G have also been showcased.

Webcast – Press Conference

The press conference with Klaus Helmrich on November 26 was broadcast live and simultaneously translated into English.

Presentation

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The

Digital Enterprise portfolio is already well established globally in all

industries for the implementation of Industrie 4.0. Many applications

demonstrate the tangible benefits of these solutions for our customers,"

explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of

Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The

Digital Enterprise portfolio is already well established globally in all

industries for the implementation of Industrie 4.0. Many applications

demonstrate the tangible benefits of these solutions for our customers,"

explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of

Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Klaus Helmrich at the press conference during SPS 2019

"The Digital Enterprise portfolio is already well established globally in all industries for the implementation of Industrie 4.0. Many applications demonstrate the tangible benefits of these solutions for our customers," explains Klaus Helmrich, Member of the Managing Board of Siemens AG and CEO of Digital Industries, at SPS.

Booth Picture

Siemens presents extended Digital Enterprise portfolio for more effective use of digital data

At “SPS – Smart Production Solutions” 2019, Siemens is presenting industry-specific applications and future technologies for digital transformation in the manufacturing and process industry under the slogan “Digital Enterprise – Thinking industry further!”. At the heart of the over 4000 square meter booth are products, solutions and services from the Digital Enterprise portfolio, which help customers to reduce their time-to-market and to increase productivity, flexibility and environmental efficiency.

Media round table "Industrial 5G – The Wireless Network of the Future"

November 27, 2019, 10:30 – 12:00 AM

with Eckard Eberle, CEO of Siemens Process Automation and Herbert Wegmann, Head of Siemens Industrial Communication and Identification

with Eckard Eberle, CEO of Siemens Process Automation and Herbert Wegmann, Head of Siemens Industrial Communication and Identification

Sander Rotmensen talks with journalists about Industrial 5G

“5G is 10 to 20 times faster than today’s LTE and consumes only one-thousandth of the amount of energy per bit transferred. Low latencies, extremely high bandwidths, control over one’s own data, having control over the network performance – private networks open up previously unimagined opportunities for industry,” says Sander Rotmensen (links), Head of Product Management for Industrial Wireless Communication at Siemens. Right: Eckard Eberle, CEO Process Automation at Siemens

Eckard Eberle talks with journalists about Industrial 5G

“Industrial 5G is the gateway to an all-encompassing, wireless network for production, maintenance, and logistics. High data rates, ultra-reliable transmission, and extremely low latencies will allow significant increases in efficiency and flexibility in industrial added value,” says Eckard Eberle (right), CEO Process Automation at Siemens. Left: Sander Rotmensen, Head of Product Management for Industrial Wireless Communication at Siemens

Eckard Eberle talks with journalists about Industrial 5G

“Industrial 5G is the gateway to an all-encompassing, wireless network for production, maintenance, and logistics. High data rates, ultra-reliable transmission, and extremely low latencies will allow significant increases in efficiency and flexibility in industrial added value,” says Eckard Eberle (right), CEO Process Automation at Siemens. Left: Sander Rotmensen, Head of Product Management for Industrial Wireless Communication at Siemens

Eckard Eberle talks with journalists about Industrial 5G

“Industrial 5G is the gateway to an all-encompassing, wireless network for production, maintenance, and logistics. High data rates, ultra-reliable transmission, and extremely low latencies will allow significant increases in efficiency and flexibility in industrial added value,” says Eckard Eberle, CEO Process Automation at Siemens.

Sander Rotmensen talks with journalists about Industrial 5G

“5G is 10 to 20 times faster than today’s LTE and consumes only one-thousandth of the amount of energy per bit transferred. Low latencies, extremely high bandwidths, control over one’s own data, having control over the network performance – private networks open up previously unimagined opportunities for industry,” says Sander Rotmensen (links), Head of Product Management for Industrial Wireless Communication at Siemens. Right: Eckard Eberle, CEO Process Automation at Siemens

Sander Rotmensen talks with journalists about Industrial 5G

“5G is 10 to 20 times faster than today’s LTE and consumes only one-thousandth of the amount of energy per bit transferred. Low latencies, extremely high bandwidths, control over one’s own data, having control over the network performance – private networks open up previously unimagined opportunities for industry,” says Sander Rotmensen (links), Head of Product Management for Industrial Wireless Communication at Siemens. Right: Eckard Eberle, CEO Process Automation at Siemens

Eckard Eberle talks with journalists about Industrial 5G

“Industrial 5G is the gateway to an all-encompassing, wireless network for production, maintenance, and logistics. High data rates, ultra-reliable transmission, and extremely low latencies will allow significant increases in efficiency and flexibility in industrial added value,” says Eckard Eberle (right), CEO Process Automation at Siemens. Left: Sander Rotmensen, Head of Product Management for Industrial Wireless Communication at Siemens

Eckard Eberle talks with journalists about Industrial 5G

“Industrial 5G is the gateway to an all-encompassing, wireless network for production, maintenance, and logistics. High data rates, ultra-reliable transmission, and extremely low latencies will allow significant increases in efficiency and flexibility in industrial added value,” says Eckard Eberle (right), CEO Process Automation at Siemens. Left: Sander Rotmensen, Head of Product Management for Industrial Wireless Communication at Siemens

Eckard Eberle talks with journalists about Industrial 5G

“Industrial 5G is the gateway to an all-encompassing, wireless network for production, maintenance, and logistics. High data rates, ultra-reliable transmission, and extremely low latencies will allow significant increases in efficiency and flexibility in industrial added value,” says Eckard Eberle, CEO Process Automation at Siemens.

Sander Rotmensen talks with journalists about Industrial 5G

“5G is 10 to 20 times faster than today’s LTE and consumes only one-thousandth of the amount of energy per bit transferred. Low latencies, extremely high bandwidths, control over one’s own data, having control over the network performance – private networks open up previously unimagined opportunities for industry,” says Sander Rotmensen (links), Head of Product Management for Industrial Wireless Communication at Siemens. Right: Eckard Eberle, CEO Process Automation at Siemens

Sander Rotmensen talks with journalists about Industrial 5G

“5G is 10 to 20 times faster than today’s LTE and consumes only one-thousandth of the amount of energy per bit transferred. Low latencies, extremely high bandwidths, control over one’s own data, having control over the network performance – private networks open up previously unimagined opportunities for industry,” says Sander Rotmensen (links), Head of Product Management for Industrial Wireless Communication at Siemens. Right: Eckard Eberle, CEO Process Automation at Siemens

Eckard Eberle talks with journalists about Industrial 5G

“Industrial 5G is the gateway to an all-encompassing, wireless network for production, maintenance, and logistics. High data rates, ultra-reliable transmission, and extremely low latencies will allow significant increases in efficiency and flexibility in industrial added value,” says Eckard Eberle (right), CEO Process Automation at Siemens. Left: Sander Rotmensen, Head of Product Management for Industrial Wireless Communication at Siemens

Press releases on products and solutions

Press Release06 November 2019

Siemens’ new Sirius soft starters enable safe, efficient motor switching

- First soft starter series with integrated Safe Torque Off function...

Press Release30 October 2019

T-Systems and Siemens partner to drive the digitalization of German industry

T-Systems and Siemens today announced a partnership to offer new end-to-end solutions that combine their respective capabilities i...

Press Release01 October 2019

Web-based visualization system sets new standards for industrial operator control and monitoring

- Simatic WinCC Unified: Completely new developed visualization system based on native Web technologies...

Press Release26 November 2019

Siemens Industrial Edge takes the benefits of the Cloud to field level

- Siemens Industrial Edge closes the gap between local and Cloud computing and enables high-frequency data exchange at field level...

Press Release26 November 2019

Engineering framework ready for continuous software development

- New Version V16 of the TIA Portal engineering framework with focus on standardization and continuous integration...

Press Release26 November 2019

Siemens and Qualcomm Technologies set up the first private standalone 5G network in an industrial environment

- Sustainable technological cooperation for the future of industrial wireless communication

- Joint Proof of Concept in a real industrial environment using the 3.7-3.8 GHz band

- Researching the capabilities of 5G standalone networks for industrial applications

Press Release26 November 2019

Siemens launches new starters for smaller motors and improved system monitoring

- New devices for electrical installations in industrial and infrastructure environments with a lower nominal current of 0.1 to 0.4 amperes...

Press Release25 November 2019

Analyze MyDrives V1.0 available as standard in MindSphere Store and Sinamics Connect 300 with new intelligent features

At SPS 2019, Siemens presents its latest solutions for smart and networked drive technology. By networking entire drive systems, m...

Press Release21 November 2019

Simatic Micro-Drive F-TM Servodrive adds protective extra-low voltage range to the drive portfolio

- Easy connection to Simatic controllers using plug-in connectors...

Press Release21 November 2019

New measuring devices from Siemens capture energy data with higher accuracy

- Exact recording of energy consumption and electrical parameters...

Press Release19 November 2019

Simatic Drive Controller – the new motion controller with integrated drive control

- Simatic S7-1500 controller with expanded motion control functionality and Sinamics S120 drive control in one device – thus saving space...

Press Release06 November 2019

New Mindsphere app from Siemens supports Predictive Services for Drive Systems

- Efficient and future-proof maintenance with Predictive Services for Drive Systems...

Press Release06 November 2019

Siemens’ new Sirius soft starters enable safe, efficient motor switching

- First soft starter series with integrated Safe Torque Off function...

Press Release30 October 2019

T-Systems and Siemens partner to drive the digitalization of German industry

T-Systems and Siemens today announced a partnership to offer new end-to-end solutions that combine their respective capabilities i...

Press Release01 October 2019

Web-based visualization system sets new standards for industrial operator control and monitoring

- Simatic WinCC Unified: Completely new developed visualization system based on native Web technologies...

Press Release26 November 2019

Siemens Industrial Edge takes the benefits of the Cloud to field level

- Siemens Industrial Edge closes the gap between local and Cloud computing and enables high-frequency data exchange at field level...

Press Release26 November 2019

Engineering framework ready for continuous software development

- New Version V16 of the TIA Portal engineering framework with focus on standardization and continuous integration...

Press Release26 November 2019

Siemens and Qualcomm Technologies set up the first private standalone 5G network in an industrial environment

- Sustainable technological cooperation for the future of industrial wireless communication

- Joint Proof of Concept in a real industrial environment using the 3.7-3.8 GHz band

- Researching the capabilities of 5G standalone networks for industrial applications

Press Release26 November 2019

Siemens launches new starters for smaller motors and improved system monitoring

- New devices for electrical installations in industrial and infrastructure environments with a lower nominal current of 0.1 to 0.4 amperes...

Press Release25 November 2019

Analyze MyDrives V1.0 available as standard in MindSphere Store and Sinamics Connect 300 with new intelligent features

At SPS 2019, Siemens presents its latest solutions for smart and networked drive technology. By networking entire drive systems, m...

Press Release21 November 2019

Simatic Micro-Drive F-TM Servodrive adds protective extra-low voltage range to the drive portfolio

- Easy connection to Simatic controllers using plug-in connectors...

Press Release21 November 2019

New measuring devices from Siemens capture energy data with higher accuracy

- Exact recording of energy consumption and electrical parameters...

Press Release19 November 2019

Simatic Drive Controller – the new motion controller with integrated drive control

- Simatic S7-1500 controller with expanded motion control functionality and Sinamics S120 drive control in one device – thus saving space...

Press Release06 November 2019

New Mindsphere app from Siemens supports Predictive Services for Drive Systems

- Efficient and future-proof maintenance with Predictive Services for Drive Systems...

Press Release06 November 2019

Siemens’ new Sirius soft starters enable safe, efficient motor switching

- First soft starter series with integrated Safe Torque Off function...

Press Release30 October 2019

T-Systems and Siemens partner to drive the digitalization of German industry

T-Systems and Siemens today announced a partnership to offer new end-to-end solutions that combine their respective capabilities i...

Press Release01 October 2019

Web-based visualization system sets new standards for industrial operator control and monitoring

- Simatic WinCC Unified: Completely new developed visualization system based on native Web technologies...

Siemens presents extended Digital Enterprise portfolio for more effective use of digital data

At “SPS – Smart Production Solutions” 2019, Siemens is presenting industry-specific applications and future technologies for digital transformation in the manufacturing and process industry under the slogan “Digital Enterprise – Thinking industry further!”. At the heart of the over 4000 square meter booth are products, solutions and services from the Digital Enterprise portfolio, which help customers to reduce their time-to-market and to increase productivity, flexibility and environmental efficiency.

Web-based visualization system sets new standards for industrial operator control and monitoring

At the "SPS – Smart Production Solutions" 2019, Siemens will present a completely new overall system for industrial operator control and monitoring. The web-based visualization system consists initially the Simatic WinCC Unified visualization software as well as the new generation of HMI panels, Simatic HMI Unified Comfort Panels.

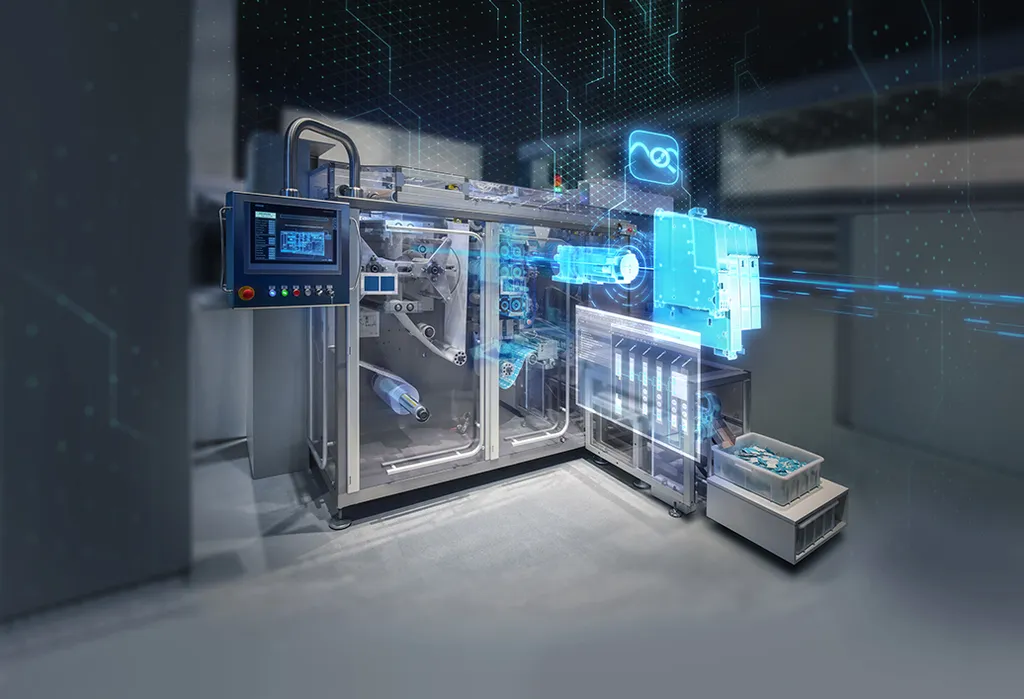

Siemens Industrial Edge takes the benefits of the Cloud to field level

With Siemens Industrial Edge, Siemens offers a digitalization solution that adds machine-level data processing to automation devices, by taking the intelligence of Edge computing and thus, sophisticated analytics securely to manufacturing level. Siemens Industrial Edge offers users the opportunity to execute a wide range of descriptive, diagnostic, predictive and prescriptive analytics applications. Cloud connectivity is used in conjunction with Edge apps from Siemens, from third-party providers or from users themselves in an integrated hardware and software ecosystem for automation components.

Engineering framework ready for continuous software development

With the new TIA Portal V16 (Totally Integrated Automation Portal), Siemens has expanded its engineering framework with practical new functions for various phases from planning, to engineering, to commissioning. The innovations concentrate on the continuous integration of the development process. These include standardization, integrated engineering spread across teams and an integrated function test. This enables users to increase the quality of their software, shorten commissioning times and reduce engineering costs.

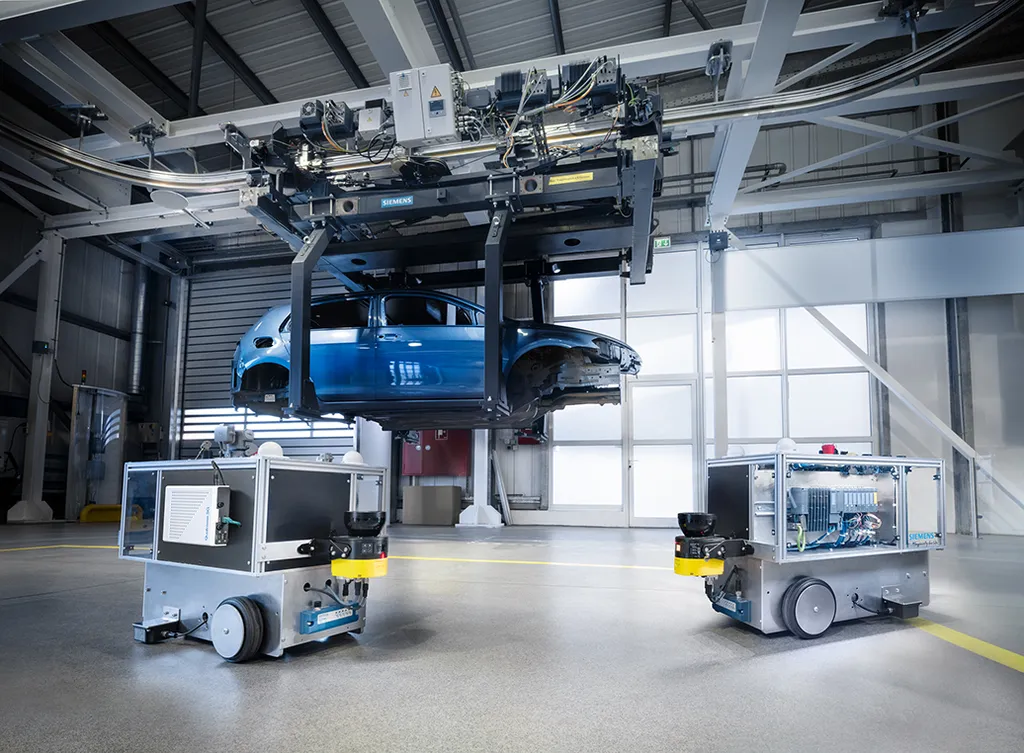

Siemens and Qualcomm Technologies set up the first private standalone 5G network in an industrial environment

Siemens and Qualcomm Technologies, Inc. have implemented the first private 5G standalone (SA) network in a real industrial environment using the 3.7-3.8GHz band. Both companies have joined forces in this project: Siemens is providing the actual industrial test conditions and end devices such as Simatic control systems and IO devices and Qualcomm Technologies is supplying the 5G test network and the relevant test equipment. The 5G network was installed in Siemens’ Automotive Showroom and Test Center in Nuremberg. Automated guided vehicles are (AGV) displayed here which are primarily used in the automotive industry. New manufacturing options and methods are also developed, tested and presented before they are put into action on customer sites. This allows Siemens’ customers, such as automated guided vehicle manufacturers, to see the products interact live.

Siemens launches new starters for smaller motors and improved system monitoring

Siemens Smart Infrastructure is adding four new devices to its portfolio of Simatic ET 200SP motor starters, which can be used to start electric drives with a power output from 0.1 to 0.4 amperes (A). These types of drives are found in fans and coolant pumps, for example. The compact motor starters are installed in control cabinets and are designed to start single and three-phase motors of machines and systems, protecting them against overloads and short-circuits. They are each available in standard and safety variants.

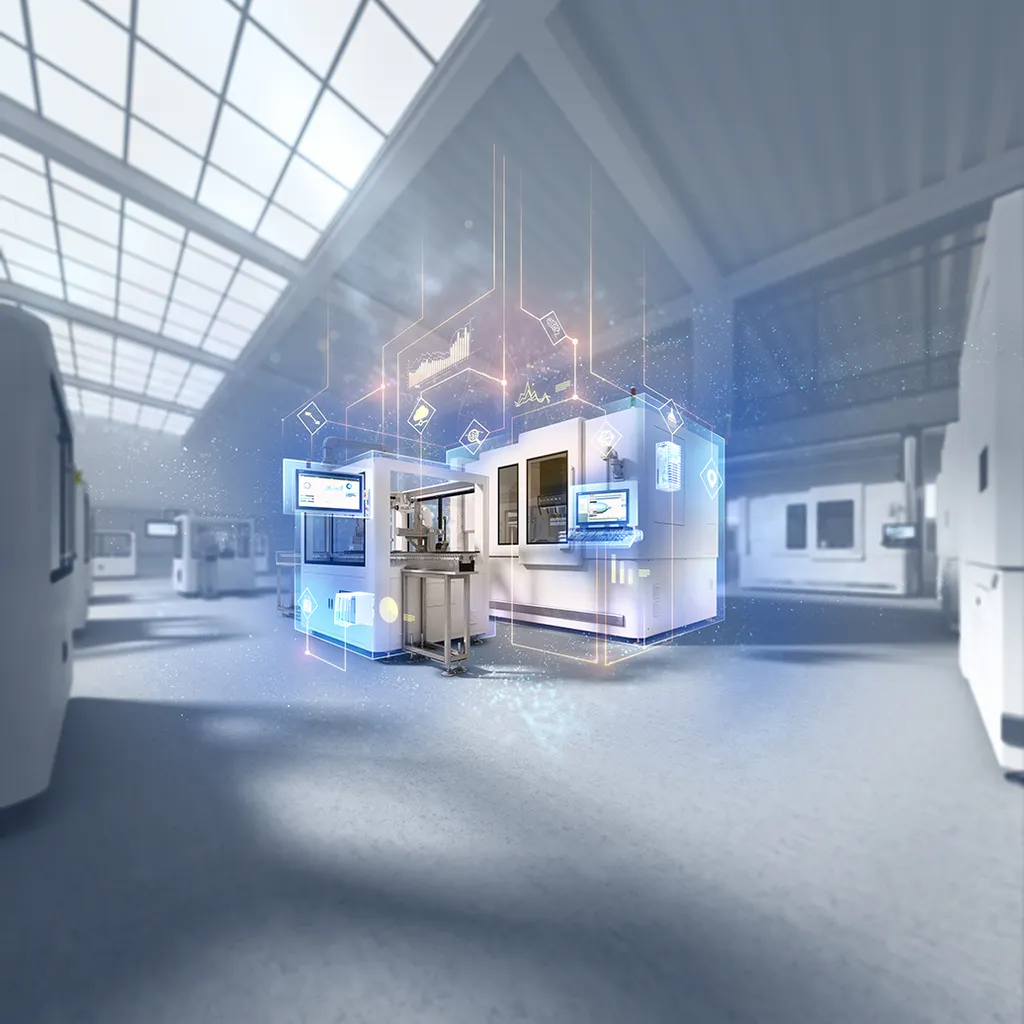

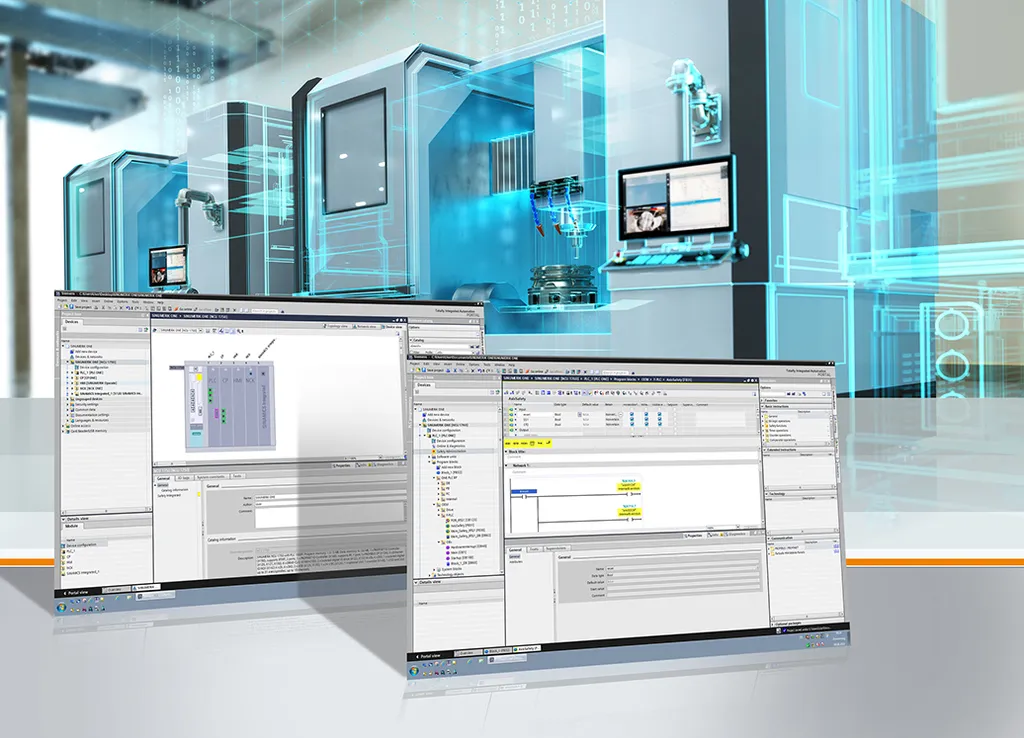

Sinumerik One in the TIA Portal

The new Sinumerik One

CNC generation is at the heart of digital transformation for machine tools. As

a digital native, the controller features not only a new hardware platform, but

also versatile software for the creation of a digital twin. It closes the gap

between the virtual and the real world and helps to reduce development and

commissioning times considerably.

Simatic Micro-Drive F-TM Servodrive adds protective extra-low voltage range to the drive portfolio

Simatic Micro-Drive F-TM Servodrive is the newest member of the Simatic Micro-Drive family. The servo drive system comprises a Simatic Micro-Drive F-TM Servodrive drive controller module, the Simatic ET 200SP and universal motors and plug-in cables. It adds to the Simatic Micro-Drive PDC (ProfiDriveControl) and completes the drive portfolio in the protective extra-low voltage range for EC motors from 24 to 48 volts. The drive controller module supports dynamic and accurate positioning in a small amount of space in the performance range up to 280 watts.

New measuring devices from Siemens capture energy data with higher accuracy

Siemens Smart Infrastructure has added the 7KM PAC3220 and 7KM PAC3120 measuring devices to its Sentron power monitoring portfolio. These devices capture energy and system data from buildings, infrastructure and industrial facilities and transfer them via standard communication protocols to higher-level energy management, automation and IoT systems. This data can then be used to identify energy hogs, detect system malfunctions as early as possible and proactively prevent downtimes. This allows companies to sustainably boost their energy efficiency and system availability. The new devices offer higher accuracy than the previous models and have a new design.

Siemens presents extended Digital Enterprise portfolio for more effective use of digital data

At “SPS – Smart Production Solutions” 2019, Siemens is presenting industry-specific applications and future technologies for digital transformation in the manufacturing and process industry under the slogan “Digital Enterprise – Thinking industry further!”. At the heart of the over 4000 square meter booth are products, solutions and services from the Digital Enterprise portfolio, which help customers to reduce their time-to-market and to increase productivity, flexibility and environmental efficiency.

Web-based visualization system sets new standards for industrial operator control and monitoring

At the "SPS – Smart Production Solutions" 2019, Siemens will present a completely new overall system for industrial operator control and monitoring. The web-based visualization system consists initially the Simatic WinCC Unified visualization software as well as the new generation of HMI panels, Simatic HMI Unified Comfort Panels.

Siemens Industrial Edge takes the benefits of the Cloud to field level

With Siemens Industrial Edge, Siemens offers a digitalization solution that adds machine-level data processing to automation devices, by taking the intelligence of Edge computing and thus, sophisticated analytics securely to manufacturing level. Siemens Industrial Edge offers users the opportunity to execute a wide range of descriptive, diagnostic, predictive and prescriptive analytics applications. Cloud connectivity is used in conjunction with Edge apps from Siemens, from third-party providers or from users themselves in an integrated hardware and software ecosystem for automation components.

Engineering framework ready for continuous software development

With the new TIA Portal V16 (Totally Integrated Automation Portal), Siemens has expanded its engineering framework with practical new functions for various phases from planning, to engineering, to commissioning. The innovations concentrate on the continuous integration of the development process. These include standardization, integrated engineering spread across teams and an integrated function test. This enables users to increase the quality of their software, shorten commissioning times and reduce engineering costs.

Siemens and Qualcomm Technologies set up the first private standalone 5G network in an industrial environment

Siemens and Qualcomm Technologies, Inc. have implemented the first private 5G standalone (SA) network in a real industrial environment using the 3.7-3.8GHz band. Both companies have joined forces in this project: Siemens is providing the actual industrial test conditions and end devices such as Simatic control systems and IO devices and Qualcomm Technologies is supplying the 5G test network and the relevant test equipment. The 5G network was installed in Siemens’ Automotive Showroom and Test Center in Nuremberg. Automated guided vehicles are (AGV) displayed here which are primarily used in the automotive industry. New manufacturing options and methods are also developed, tested and presented before they are put into action on customer sites. This allows Siemens’ customers, such as automated guided vehicle manufacturers, to see the products interact live.

Siemens launches new starters for smaller motors and improved system monitoring

Siemens Smart Infrastructure is adding four new devices to its portfolio of Simatic ET 200SP motor starters, which can be used to start electric drives with a power output from 0.1 to 0.4 amperes (A). These types of drives are found in fans and coolant pumps, for example. The compact motor starters are installed in control cabinets and are designed to start single and three-phase motors of machines and systems, protecting them against overloads and short-circuits. They are each available in standard and safety variants.

Sinumerik One in the TIA Portal

The new Sinumerik One

CNC generation is at the heart of digital transformation for machine tools. As

a digital native, the controller features not only a new hardware platform, but

also versatile software for the creation of a digital twin. It closes the gap

between the virtual and the real world and helps to reduce development and

commissioning times considerably.

Simatic Micro-Drive F-TM Servodrive adds protective extra-low voltage range to the drive portfolio

Simatic Micro-Drive F-TM Servodrive is the newest member of the Simatic Micro-Drive family. The servo drive system comprises a Simatic Micro-Drive F-TM Servodrive drive controller module, the Simatic ET 200SP and universal motors and plug-in cables. It adds to the Simatic Micro-Drive PDC (ProfiDriveControl) and completes the drive portfolio in the protective extra-low voltage range for EC motors from 24 to 48 volts. The drive controller module supports dynamic and accurate positioning in a small amount of space in the performance range up to 280 watts.

New measuring devices from Siemens capture energy data with higher accuracy

Siemens Smart Infrastructure has added the 7KM PAC3220 and 7KM PAC3120 measuring devices to its Sentron power monitoring portfolio. These devices capture energy and system data from buildings, infrastructure and industrial facilities and transfer them via standard communication protocols to higher-level energy management, automation and IoT systems. This data can then be used to identify energy hogs, detect system malfunctions as early as possible and proactively prevent downtimes. This allows companies to sustainably boost their energy efficiency and system availability. The new devices offer higher accuracy than the previous models and have a new design.

Siemens presents extended Digital Enterprise portfolio for more effective use of digital data

At “SPS – Smart Production Solutions” 2019, Siemens is presenting industry-specific applications and future technologies for digital transformation in the manufacturing and process industry under the slogan “Digital Enterprise – Thinking industry further!”. At the heart of the over 4000 square meter booth are products, solutions and services from the Digital Enterprise portfolio, which help customers to reduce their time-to-market and to increase productivity, flexibility and environmental efficiency.

Web-based visualization system sets new standards for industrial operator control and monitoring

At the "SPS – Smart Production Solutions" 2019, Siemens will present a completely new overall system for industrial operator control and monitoring. The web-based visualization system consists initially the Simatic WinCC Unified visualization software as well as the new generation of HMI panels, Simatic HMI Unified Comfort Panels.

MediaService Digital Industries

Further SPS Events

Contact

Link to this page

www.siemens.com/press/sps19

www.siemens.com/press/sps19