Extended Digital Enterprise Suite for the discrete industries

"With our extended portfolio of software-based systems and leading automation technologies across the entire value chain, we're helping support the discrete industries on their way to the digital transformation. And we're continuing to expand our lead in this field: Firstly by completing our portfolio with further acquisitions. These include the planned takeovers of TASS, a worldwide supplier of simulation software as well as engineering and test services focusing on the automotive industry, and Infolytica, a supplier of software tools for electromagnetic simulation in the low-frequency range. At the same time, we're continuing to develop our software and hardware offering", explains Jan Mrosik, CEO of the Digital Factory Division. "Examples of this include the TIA Portal, which allows engineering work to be reduced by up to 30 percent, or MindSphere, our open cloud-based operating system for the Internet of Things. This enables companies from across wide-ranging industries to develop new digital services and business models."

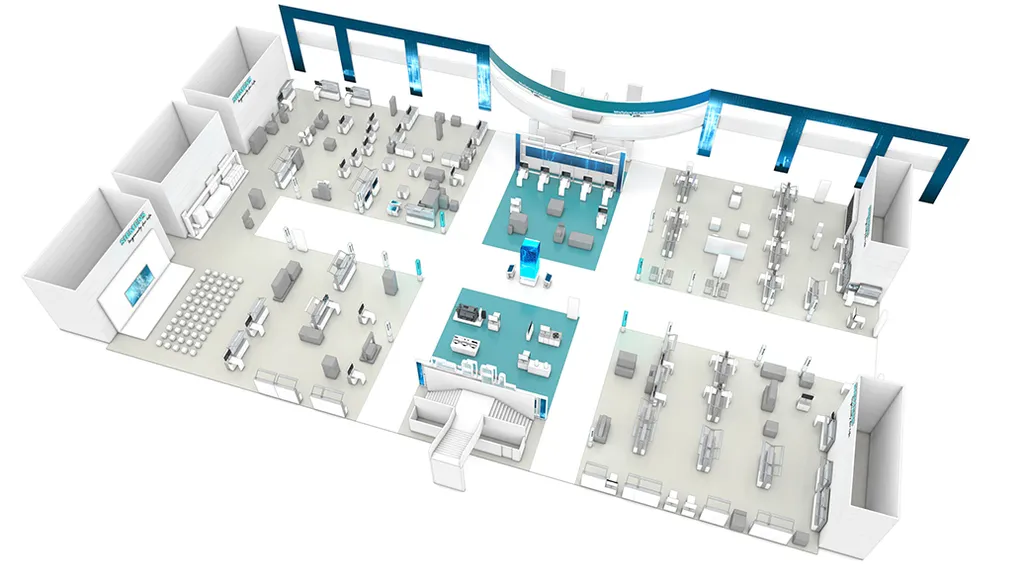

Because of its open architecture, the ecosystem surrounding the open cloud-based IoT operating system MindSphere continues to expand. This is reflected in the increased size of this year's MindSphere Lounge, which now covers an area of 1,400 sq.m. Here, together with around 20 partner companies such as Amazon Web Services, Atos, Evosoft and Rittal, Siemens will be demonstrating the diverse application and connection scope of the system. The exhibition will also feature machine and plant builders presenting new services and business models based on MindSphere, which permit the improvement of factors such as efficiency and productivity.

At the SPS IPC Drives, Siemens will be presenting the latest release of the TIA Portal, V15, which provides added ways of improving engineering efficiency – such as simplified robotics integration. Virtual commissioning with PLCSIM Advanced and Version 12 of the NX MCD software allows complete machines to be tested and optimized in terms of both function and performance – meaning a significant reduction in total engineering time.

Illustrating the convergence between the virtual and the real production worlds, at the fair will be an exhibit featuring a high-performance filling and sealing machine for the pharmaceutical industry built by Bausch + Ströbel. This company plans to use integrated hardware and software solutions from Siemens to achieve a 30 percent improvement of its engineering efficiency by 2020 by consistently applying digitalization across its entire value chain.

Innovations enabling digital transformation of the process industries

End-to-end optimized processes which serve current market demands with the utmost flexibility and efficiency help to sharpen competitive standing in the process industries. The Digital Enterprise for the process industry with the digital twin at its core helps users to speed up the digital transformation of their facilities. "Our domain expertise creates the foundation for optimizing every process across the entire life cycle – even in already existing plants," says Jürgen Brandes, CEO of the Process Industries and Drives Division. "A concrete example of this is the new IoT-capable drive concept Simotics IQ. Equipped with functions capable of capturing motor data and integrated MindSphere connectivity – Simotics Connect – it enables data-based services, for instance in the field of predictive maintenance, which open up scope for new business models for our customers, such as the sale of compressed air instead of compressors."

The digital twin also offers decisive benefits when it comes to plant optimization – from the engineering stage through operation to maintenance. Here, the latest version 9.1 of the Simit simulation software enables the virtual commissioning of plants to be even more simply combined with operator training. This allows users to speed up the actual commissioning process by as much as 60 percent, and particularly for plant conversion or migration projects, to reduce downtimes to an absolute minimum.

Siemens will also be showcasing the use of innovative IT technologies which enable existing plants to be recorded, digitalized using imaging software and then optimized – for instance through the use of drones. This creates the conditions for an entry into the world of digitalization tailored precisely to individual needs, benefitting particularly customers in the process industries, where there is a predominance of brownfield plants designed for long-term use.

In the field of industrial communication networks and industrial security, featured innovations will include new security network components known as Cyber Security Appliances. These are used as part of the comprehensive Siemens security concept to help minimize cyber risk for industrial enterprises.

Electrical power distribution in digital industrial environments

Electrical power distribution also relies on the trouble-free interaction between hardware and software using systematic data management to support networked production processes. The products and systems used have to enable seamless integration into the automation environment: starting with the electrotechnical planning of control cabinets based on the digital twin, through integration of communication-capable components into the automation system, to the acquisition of energy and plant-related data and its provision in MindSphere. In this way, operational energy efficiency and plant availability can be substantially increased, operating sequences and maintenance optimized and the entire value adding process in the control cabinet and plant building process simplified. "At the SPC IPC Drives in Nuremberg, we'll be demonstrating many different examples of digital power distribution," says Ralf Christian, CEO of the Energy Management Division. "Using a producing machine, we'll be demonstrating the electrotechnical planning of a control cabinet based on a digital twin, and also the acquisition of energy and plant data and its link-up to MindSphere." The Siemens Energy Management Division brings together its extensive portfolio of software and digital services under "MindSphere for Energy".

Siemens will also be demonstrating digital power distribution at the Sivacon S8 low-voltage switchboard. Used in conjunction with the Simaris control planning tool, it can be used to operate and monitor communication-capable switchgear and motor controls both locally and remotely. Data gathered by the switchboard is made available to higher-level automation systems, energy management systems and in MindSphere.